It's good to know

Q & A's

What are ultrasounds?

Ultrasounds are basically sound waves with a frequency between 16 kHz and 1 GHz.

Human cannot hear it, however they are easily found when touching welding machines with its wide application within industrial conditions. Ultrasound vibrations occur as oblong waves being changed into heat and are able to change the shape of plastics and cause friction between particles. Those processes enable precise cutting, brazing, cleaning and joining of elements of different shapes and structures. It is worth mentioning, that ultrasound frequencies between 20 and 35 kHz are not harmful for humans and animals.

Read more ...

Human cannot hear it, however they are easily found when touching welding machines with its wide application within industrial conditions. Ultrasound vibrations occur as oblong waves being changed into heat and are able to change the shape of plastics and cause friction between particles. Those processes enable precise cutting, brazing, cleaning and joining of elements of different shapes and structures. It is worth mentioning, that ultrasound frequencies between 20 and 35 kHz are not harmful for humans and animals.

Read more ...

Does Sonictech offer support to clients?

Of course, we do. Our clients receive specialized help for both selecting the required equipment, as well as servicing, repairs, calibrating and software updates.

We also offer post guarantee servicing.

We also offer post guarantee servicing.

Do I need ultrasound technology in my production process?

The simple answer is: Yes, if you care about fast processes and repetitive welding effects . Having said that it is not a technology for every single company. The best possible quality when it comes to durability, robustness and aesthetics can be obtained when the materials of parts and constructions are suitable for the ultrasound process.

Ultrasound technology is recommended for multi-series production, especially within automotive, electrical, medical, packaging and hygiene industry. It ensures economical, aesthetical, clean, comfortable and what is most important permanent components joint.

Ultrasound technology is recommended for multi-series production, especially within automotive, electrical, medical, packaging and hygiene industry. It ensures economical, aesthetical, clean, comfortable and what is most important permanent components joint.

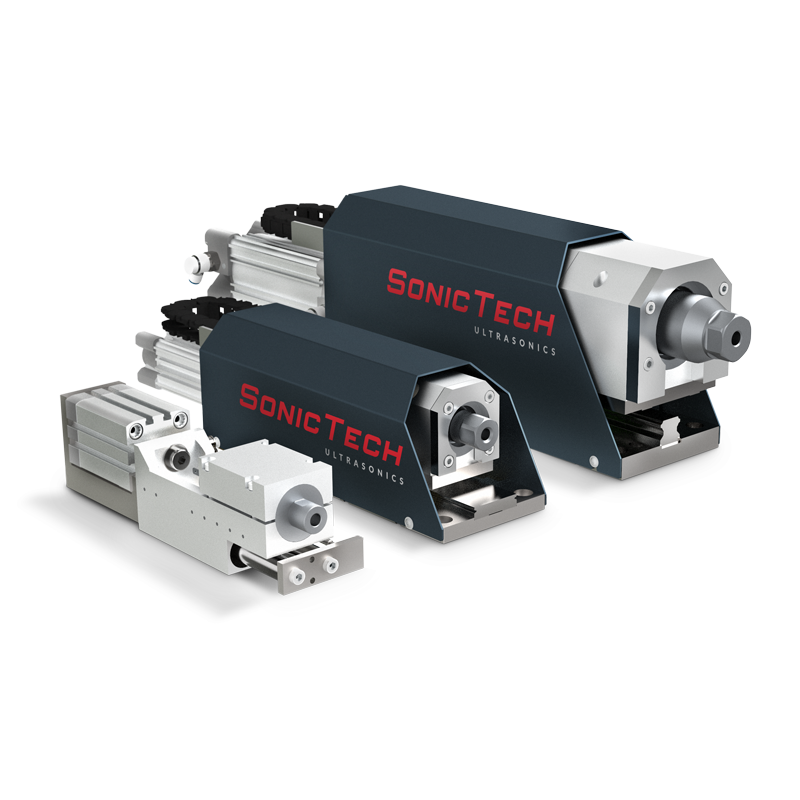

What does ultrasound welding process look like?

Ultrasound joining of thermoplastic materials is a technology of welding by using mechanical vibrations to generate heat because of molecular friction. Irreplaceable part is a sonotrode being a welding tool , carrying vibrations onto the components.

Those vibrations cause the movement of molecules in plastics which become soft and start melting . Thanks to that the components are joined or adjusted to the joint shape. After a short period of time under pressure the materials are permanently molecularly joint.

Those vibrations cause the movement of molecules in plastics which become soft and start melting . Thanks to that the components are joined or adjusted to the joint shape. After a short period of time under pressure the materials are permanently molecularly joint.